The areas where innovation determines the order of the day, there is often something new to report. Today, the postpress industry faces new challenges almost every day, and we at Hohner are already working feverishly today on the solutions of tomorrow and the day after. We can promise you that there will be interesting news from Hohner also in the future! Come back and visit us here from time to time and learn about new ideas and approaches, promising collaboration, innovative products and solutions, and much more...

Hohner's latest developments promise enhanced flexibility and cost-effectiveness. For instance, the fully automated HSB 13.000, boasting a 180-second makeready time, will be spotlighted within a fully networked, automated workflow from printing to the stitched brochure, culminating in an automated surprise, aligning with the stand's motto.

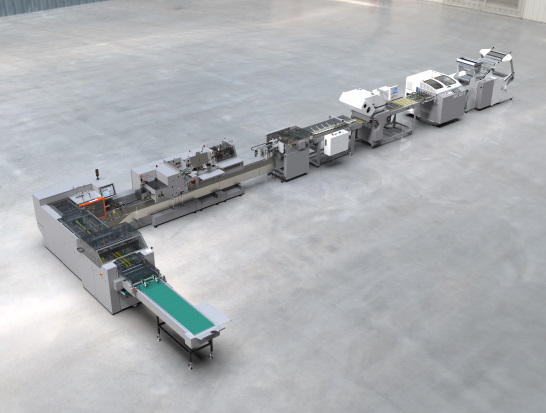

The modular saddle stitcher HHS Futura, renowned for saddle stitching expertise, will unveil two digital processing modes: MBO's unwinder, cross-cutter, and folding machine components, alongside H+H's transfer table, facilitating roll processing. The Hohner KDAL compact digital sheet feeder ensures digitally controlled non-stop sheet feeding. The Futura seamlessly executes data matrix code-controlled collating of variable content with utmost production reliability, incorporating automated variable-thickness stitching and 3-sided trimming, significantly reducing personnel requirements.

Digitization and print products are not mutually exclusive; rather, they complement each other. Digital technology offers new and efficient production methods in print finishing.

The HHS Futura, with its array of loading alternatives, open interfaces, and capability to integrate existing components and units, emerges as possibly the most modular and flexible saddle stitcher concept available today. Hohner offers the modern print store a long-term adaptable future because where it says Futura, there is a future in it.